- Packaging Bags[1]

- Toaster Oven Parts[1]

- BBQ Accessories[2]

- Other Cooking Tools[2]

- BBQ Grills[1]

- Mats & Pads[1]

- Other Packaging Materials[1]

- Plasterboards[1]

- Fiberglass Cloth[6]

- Other Firefighting Supplies[1]

- Transmission Belts[1]

- Other Ceramic Fiber Products[1]

- Carbon Fiber Fabric[1]

- Other Non-Metallic Minerals & Products[2]

- Mat[1]

- Door & Window Screens[6]

- Fiberglass Yarn[1]

- Other Fiberglass Products[6]

- Other Fireproofing Materials[5]

- Other Fabric[6]

- Pipe Fittings[1]

- Fire Suit[1]

- Thread[2]

- Sewing Threads[2]

- Fiberglass Mesh[4]

- Fiberglass Mat[3]

- Insulation Materials & Elements[1]

- Garment Bags[1]

- Sewing Machines[1]

- Fire Blanket[3]

- Blanket[1]

- Shutters[1]

- Rayon/Polyester Fabric[1]

- Shade Sails & Nets[1]

- Filter Cloth[2]

- Other Household Cleaning Tools & Accessories[1]

- Other Filter Supplies[2]

- Consumer Electronics Production Lines[1]

- Awnings[1]

- Curtain[2]

- Grey Fabric[1]

- 100% Polyester Fabric[1]

- Filter Meshes[1]

- Contact Person : Ms. chen lucy

- Company Name : Wuxi First Special-Type Fiberglass Co., Ltd.

- Tel : 0086-0510-80229966

- Fax : 0510-80229955

- Address : Jiangsu,wuxi,yanqiao industry park

- Country/Region : China

- Zip : 214174

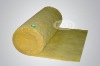

fiberglass chopped strand mat

1. Product profile:

This product is lamellar product made of fiberglass filament or roving yarn which cut short into 50mm and by the process of chemical gluing and mechanical operation.

2. Product application and requests:

Manual shaping: manual shaping process is the main method to produce glass-steel in our country; fiberglass chopped felt is used in manual shaping process, it could helps to decrease the frequency of spreading layer and increase the efficiency of manual working. Manual shaping process requests the felts have characteristics of high speed of soaking gum, easy erasing bladder and good capability of submerging mould.

Twisting process: usually it use chopped mat or sequence mat to twist into gum layer which mainly used to make into product, containing internal layer and external surface. The requests of twisting process to fiberglass are similar to that of manual shaping process.

Eccentric foundry shaping: generally use chopped mat as raw material. Firstly spread the chopped into the mould, then put the gum into the gyrating opening module, by eccentric to discharge bladder and make the product become denser. This process requests the felt has good capability of easy soaking and passing though air.

Generally, the chopped felt is used in manufacturing products with homogeneous section and medium intensity, such as ship body, car element, bathroom installation, radiator and furniture, etc.

Main sorts: 300g/m*m , 450g/ m*m 600g/m*m , 800g/m*mtc.

Thickness: 100-150cm

fiberglass chopped strand mat